All Blog

The ready-made garments (RMG) sector is the largest export-earning sector of Bangladesh, contributing 84% of the country's total export earnings in FY2021-2022. The sector has been growing at a rapid pace in recent years, and is now the second largest apparel exporter in the world after China. The RMG sector has made a significant contribution to the economic growth of Bangladesh. In FY2022, the sector contributed 9.25% to the country's GDP. The sector has also created millions of jobs, directly and indirectly, and has helped to reduce poverty. The RMG sector is facing a number of challenges, including rising labor costs, competition from other low-cost countries, and the need to improve quality and productivity. However, the sector is well-positioned to continue to grow in the coming years, as demand for apparel continues to grow in the global market. Here are some of the ways in which the RMG sector has contributed to economic growth in Bangladesh: Export earnings: The RMG sector is the largest export-earning sector of Bangladesh, contributing 84% of the country's total export earnings in FY2022. This has helped to boost the country's foreign exchange reserves and has made a significant contribution to the national economy. Job creation: The RMG sector has created millions of jobs, directly and indirectly. In FY2022, the sector employed over 4 million people, directly and indirectly. This has helped to reduce poverty and improve the living standards of millions of people in Bangladesh. Economic growth: The RMG sector has contributed significantly to the economic growth of Bangladesh. In FY2022, the sector contributed 9.25% to the country's GDP. This has helped to raise the standard of living of the people of Bangladesh and has made the country a more attractive destination for investment. Employment Generation: The RMG industry is a labor-intensive sector, providing employment opportunities to millions of people, particularly women, in both urban and rural areas. It is estimated that the sector employs over 4 million workers, making it the largest formal sector employer in the country. The availability of jobs in the RMG sector has helped alleviate poverty and improve living standards for many Bangladeshis. GDP Growth: RMG exports have been a major driver of economic growth in Bangladesh. The industry's consistent growth has contributed significantly to the country's gross domestic product (GDP). It has helped maintain a positive economic growth rate, attract foreign investment, and create a conducive business environment. Industrialization and Infrastructure Development: The success of the RMG sector has led to the growth of supporting industries and infrastructure development in Bangladesh. To meet the demands of the industry, the country has witnessed the establishment of textile mills, garment factories, and other ancillary industries. This has contributed to the overall industrialization and economic development of the country. Social Transformation: The growth of the RMG sector has brought about social transformation in Bangladesh. It has empowered women by providing them with employment opportunities, financial independence, and social mobility. The sector has played a crucial role in advancing gender equality and women's empowerment. While the RMG sector has been crucial to Bangladesh's economic growth, it is worth noting that challenges such as labor rights, safety issues, environmental concerns, and global market competition remain. The government and industry stakeholders are working to address these challenges and ensure sustainable growth in the sector. Overall, the ready-made garments exports earning has been a vital component of Bangladesh's economic growth, contributing significantly to employment, export revenue, industrialization, and social development.

To increase the productivity of denim items, you can consider implementing the following strategies: Streamline the production process: Analyze the existing production process and identify any bottlenecks or inefficiencies. Look for ways to simplify and streamline the steps involved in manufacturing denim items. This could include optimizing the flow of materials, reorganizing workstations, or adopting lean manufacturing principles. Invest in automation: Introduce automation wherever possible to reduce manual labor and increase production speed. Automated cutting machines, sewing robots, and other advanced technologies can significantly improve productivity. Additionally, explore software solutions for inventory management, production planning, and tracking orders to enhance overall efficiency. Workforce training and skill development: Provide regular training programs to your employees to enhance their skills and knowledge. Well-trained workers can perform tasks more efficiently, reduce errors, and handle complex processes effectively, thereby increasing productivity. Cross-training employees in multiple roles also helps in maintaining flexibility and agility within the production process. Optimize production planning and scheduling: Efficient planning and scheduling are crucial for maximizing productivity. Use data analysis and forecasting techniques to estimate demand accurately and plan production accordingly. By avoiding overproduction or underproduction, you can optimize resource utilization and reduce lead times. Collaborate with suppliers: Foster strong relationships with your suppliers to ensure a smooth and reliable supply chain. Timely delivery of raw materials and other components is essential for uninterrupted production. Regularly assess your suppliers' performance and explore opportunities for optimization, such as negotiating favorable terms or seeking alternative sources. Continuous improvement and innovation: Encourage a culture of continuous improvement within your organization. Engage employees in generating ideas for productivity enhancement, process optimization, and product innovation. Regularly evaluate and implement new technologies, materials, or techniques that can improve the quality and efficiency of denim production. Implement Lean Manufacturing Principles: Adopt lean manufacturing principles such as 5S (Sort, set in order, Shine, Standardize, Sustain) to organize workspaces, eliminate clutter, and improve overall efficiency. This can help reduce downtime and improve productivity. Invest in Automation: Explore opportunities to automate repetitive and labor-intensive tasks in the denim production process. Automated cutting machines, sewing machines, and finishing equipment can significantly increase productivity while maintaining quality. Provide Training and Skill Development: Offer regular training programs for employees to enhance their skills and knowledge in denim production techniques. Well-trained workers are more efficient and produce higher-quality items in less time. Set Realistic Production Targets: Establish clear and achievable production targets based on capacity and demand. By setting realistic goals, you can motivate employees and ensure that resources are allocated appropriately. Optimize Inventory Management: Implement effective inventory management systems to avoid shortages or excess inventory. Maintaining optimal inventory levels minimizes delays and ensures a smooth production flow. Improve Communication and Collaboration: Foster a culture of open communication and collaboration among different departments involved in denim production. Clear and timely communication helps prevent misunderstandings, reduces errors, and enhances overall productivity. Implement Performance Monitoring Systems: Utilize technology to track and monitor individual and team performance. Regularly review productivity metrics and provide feedback to employees to identify areas for improvement and recognize high-performing individuals. Foster a Positive Work Environment: Create a positive and supportive work environment that encourages employee engagement and motivation. Recognize and reward employees for their efforts and contributions to boost morale and productivity. Remember that increasing productivity is an ongoing process, and it requires a combination of operational changes, technological advancements, and employee engagement. Continuously monitor and measure key performance indicators to assess the effectiveness of your efforts and make necessary adjustments as needed.

The Ready-Made Garments (RMG) industry has played a significant role in empowering women in many developing countries, particularly in South Asia. Here are some ways in which the RMG industry has contributed to women's empowerment: Employment opportunities: The RMG industry has provided employment opportunities for millions of women, especially in countries like Bangladesh, India, and Vietnam. It has created a large number of jobs in garment factories, which are often the first formal sector jobs available to women from rural areas. This has helped women gain financial independence and improve their socioeconomic status. Economic empowerment: By earning a steady income, women working in the RMG industry have been able to support themselves and their families financially. This economic empowerment has given them greater control over their lives, decision-making power within their households, and the ability to invest in their children's education and health. Skill development: The RMG industry has played a crucial role in developing the skills of women workers. Many women enter the industry with limited education or vocational training, but through their work in garment factories, they acquire valuable technical skills related to sewing, cutting, quality control, and other aspects of garment production. These skills can enhance their employability and open up opportunities for career growth. Social empowerment: The RMG industry has challenged traditional gender norms and social attitudes by providing opportunities for women to work outside their homes. This has helped shift societal perceptions about women's roles and capabilities. Women working in the industry have gained confidence, self-esteem, and a sense of empowerment, as they become active contributors to their families and communities. Collective organizing: Women working in the RMG industry have organized themselves into unions and associations to advocate for better working conditions, fair wages, and improved rights. These collective efforts have empowered women to voice their concerns, negotiate with employers, and influence policies that directly affect their lives. Through collective organizing, women have gained a stronger voice in shaping their working environments and demanding their rights. Leadership opportunities: The RMG industry has also provided leadership opportunities for women. Some women who started as garment workers have risen to managerial positions, becoming supervisors, factory managers, or even entrepreneurs in the sector. This not only offers financial rewards but also challenges gender stereotypes and inspires other women to strive for leadership roles. However, it's important to acknowledge that the RMG industry also faces challenges, such as low wages, unsafe working conditions, and limited opportunities for career advancement. Efforts are needed to address these issues and ensure that women in the industry experience true empowerment, with fair wages, safe workplaces, and access to education and training for skill development.

Here are some recycling impacts in the Ready-Made Garments (RMG) industry: ❐ Resource Conservation: Recycling in the RMG industry conserves valuable resources such as cotton, polyester, and other materials used in garment production. This reduces the need for extracting new raw materials, minimizing the industry's impact on the environment. ❐ Waste Reduction: Recycling diverts textile waste from landfills and incinerators, reducing the amount of waste generated by the RMG industry. This helps minimize environmental pollution and promotes a more sustainable waste management system. ❐ Energy Savings: Recycling textiles requires less energy compared to producing new materials. By recycling textile waste, the RMG industry can save energy throughout the recycling process, including collection, sorting, and reprocessing of materials. ❐ Water Conservation: Recycling textiles consumes less water compared to the production of virgin materials. By incorporating recycled materials into garments, the RMG industry can reduce its water footprint, contributing to water conservation efforts. ❐ Emissions Reduction: Recycling lowers greenhouse gas emissions associated with the production of new textiles. By using recycled materials, the RMG industry can reduce carbon dioxide emissions, as recycling generally requires less energy compared to manufacturing new textiles. ❐ Landfill Impact Reduction: Textile waste, if not recycled, often ends up in landfills, taking up valuable space and contributing to environmental pollution. By recycling textile waste, the RMG industry can reduce the burden on landfills and help preserve land for other purposes. ❐ Job Creation: The establishment of recycling facilities and the growth of the recycling sector within the RMG industry can create new employment opportunities, supporting local economies and contributing to job creation. ❐ Circular Economy Promotion: Recycling fosters the development of a circular economy in the RMG industry, where materials are continuously reused, recycled, or repurposed. By incorporating recycled materials into their products, RMG companies can contribute to the circularity of resources, reducing the industry's reliance on virgin materials. ❐ Innovation and Research: Embracing recycling in the RMG industry encourages innovation and research into new recycling technologies, techniques, and processes. This can lead to the development of more efficient and sustainable recycling methods, benefiting the industry as a whole. ❐ Consumer Engagement: Recycling initiatives and the use of recycled materials can enhance consumer engagement and loyalty. Many consumers today actively seek out sustainable and eco-friendly products. By promoting their recycling efforts, RMG brands can attract environmentally conscious consumers and strengthen their market position. Here are some of the ways in which the RMG industry can promote recycling: Educate factories and consumers about the importance of recycling: This can be done through workshops, seminars, and other educational initiatives. Reduce the cost of recycling: This can be done by negotiating better prices with recycling companies and by developing new recycling technologies. Improve the infrastructure for recycling: This can be done by building more recycling centers and by providing financial support to recycling companies. By taking these steps, the RMG industry can help to reduce waste, conserve resources, protect the environment, and create jobs. These recycling impacts in the RMG industry demonstrate the potential for a more sustainable and environmentally responsible approach to garment production and waste management.

The Ready-Made Garments (RMG) industry provides a wide range of job opportunities for graduates. Here are some of the common job roles available in the RMG industry: Here are some of the benefits of working in the RMG industry: High salaries: The RMG industry offers high salaries, especially for skilled workers. Opportunities for advancement: The RMG industry is a fast-paced industry, and there are many opportunities for advancement. International exposure: The RMG industry is a global industry, and there are many opportunities to work with international companies. Continuing education: The RMG industry is a constantly evolving industry, and there are many opportunities for continuing education. If you are interested in a career in the RMG industry, there are a few things you can do to prepare: Get a degree: A degree in fashion design, engineering, accounting, finance, or human resources can give you the skills and knowledge you need to succeed in the RMG industry. Get experience: Gain experience in the RMG industry through internships or entry-level jobs. Network: Network with people who work in the RMG industry. This will help you learn more about the industry and find job opportunities. The RMG industry is a great place to start your career. With hard work and dedication, you can achieve great things in this industry. ❐ Fashion Designer: Graduates with a background in fashion design can work as designers for various garment brands or design houses. They create new designs, patterns, and styles for garments, keeping in mind the latest trends and customer preferences. ❐ Merchandiser: Merchandisers play a crucial role in the RMG industry. They act as a liaison between the buyers and the manufacturers. Graduates in this role are responsible for analyzing market trends, managing production timelines, coordinating with suppliers, and ensuring that the garments are produced according to the buyer's requirements. ❐ Quality Control Manager: Quality control managers are responsible for maintaining and ensuring the quality of garments. They inspect the garments at different stages of production, conduct quality audits, and implement measures to improve quality control processes. ❐ Production Manager: Graduates can work as production managers in the RMG industry. They oversee the entire production process, manage production schedules, coordinate with different departments, and ensure that the production targets are met within the given time frame. ❐ Supply Chain Manager: Supply chain managers are responsible for managing the flow of goods from raw material suppliers to manufacturers and then to the retailers or customers. They ensure efficient inventory management, coordinate logistics, and optimize the supply chain to minimize costs and improve overall efficiency. ❐ Textile Technologist: Textile technologists work on developing and improving the materials used in garment production. They research and test different fabrics, dyes, and finishes to enhance garment quality, durability, and aesthetics. ❐ Sustainability Manager: With increasing emphasis on sustainability and ethical practices in the fashion industry, there is a growing demand for graduates who can work as sustainability managers. They develop and implement sustainable strategies, promote eco-friendly production practices, and ensure compliance with ethical standards. ❐ Fashion Buyer: Graduates with strong analytical and negotiation skills can work as fashion buyers. They identify the latest fashion trends, select garments for retail stores, negotiate with suppliers, and manage inventory to maximize sales and profitability. ❐ Pattern Maker: Pattern makers create precise patterns based on design specifications. They work closely with designers and use computer-aided design (CAD) software or manually draft patterns to be used in garment production. ❐ Garment Technologist: Garment technologists are responsible for ensuring that garments are manufactured to meet the required standards and specifications. They work on garment construction, fit, and sizing, ensuring that the garments are comfortable and well-finished. These are just a few examples of the diverse job roles available in the RMG industry. Graduates can find opportunities in various departments such as design, production, quality control, sourcing, and management, depending on their skills, interests, and educational background.

Waste management plays a crucial role in the Ready-Made Garments (RMG) sector. Given the scale of production and the associated waste generated, effective waste management practices are essential to minimize environmental impacts and promote sustainability. Here are some key aspects of waste management in the RMG sector: Waste Segregation: Proper waste segregation is the first step in effective waste management. RMG companies should implement systems to separate different types of waste, such as fabric scraps, paper, plastics, and hazardous materials. This allows for easier recycling, reuse, or proper disposal of each waste category. Recycling and Repurposing: Recycling and repurposing initiatives help divert waste from landfills. Textile waste, such as fabric cuttings or rejected garments, can be recycled into new fabrics or repurposed for different applications. By partnering with recycling facilities or engaging in in-house recycling processes, RMG companies can reduce waste and promote resource conservation. Inventory Management: Efficient inventory management practices can reduce the amount of waste generated in the RMG sector. By accurately forecasting demand, companies can minimize overproduction and avoid excess stock that may ultimately end up as waste. Lean Manufacturing: Implementing lean manufacturing principles can help reduce waste throughout the production process. By optimizing production flow, minimizing defects, and maximizing resource utilization, RMG companies can minimize waste generation and improve overall efficiency. Hazardous Waste Management: The RMG sector often deals with hazardous waste, such as chemicals, dyes, and solvents. Proper handling, storage, and disposal of these substances are essential to protect the environment and workers' health. Compliance with relevant regulations and implementation of appropriate safety measures are crucial for hazardous waste management. Waste Audits and Monitoring: Conducting regular waste audits and implementing monitoring systems allow RMG companies to identify waste generation patterns, track progress, and identify areas for improvement. This data-driven approach enables better decision-making and helps in setting waste reduction targets. Supplier Engagement: Collaborating with suppliers and encouraging sustainable practices can contribute to effective waste management in the RMG sector. Establishing clear guidelines for waste reduction and proper disposal practices throughout the supply chain promotes a more sustainable and responsible approach to waste management. Employee Awareness and Training: Educating employees about waste management practices and promoting a culture of sustainability can significantly impact waste reduction efforts. Providing training on waste segregation, recycling, and responsible disposal ensures that all staff members are actively engaged in waste management initiatives. Collaboration and Partnerships: Collaboration with recycling facilities, waste management companies, and relevant industry stakeholders can help RMG companies establish effective waste management systems. Sharing best practices, knowledge, and resources can drive continuous improvement in waste management practices. Regulatory Compliance: Compliance with local waste management regulations is essential for the RMG sector. Adhering to waste disposal, handling, and reporting requirements helps ensure legal compliance and minimizes environmental risks. Here are some of the best practices for waste management in the RMG sector: Reduce: The first step in waste management is to reduce the amount of waste that is generated. This can be done by using more efficient production methods, such as lean manufacturing. Reuse: Once waste is generated, it should be reused whenever possible. This can be done by donating used garments to charity or by recycling fabric scraps. Recycle: If waste cannot be reused, it should be recycled. This can be done by collecting and sorting waste materials and then selling them to recycling companies. Dispose of properly: If waste cannot be reused or recycled, it should be disposed of properly. This means disposing of waste in a way that does not harm the environment. By following these best practices, the RMG sector can reduce its environmental impact and improve the lives of its workers. Implementing comprehensive waste management practices in the RMG sector benefits the environment, reduces costs, and enhances the industry's sustainability. By adopting waste reduction, recycling, and responsible disposal measures, RMG companies can minimize their environmental footprint and contribute to a more sustainable future.

Sustainability plays a crucial role in the Ready-Made Garments (RMG) sector. The RMG sector encompasses the manufacturing, production, and distribution of clothing and textiles. Historically, this sector has faced numerous sustainability challenges, including environmental impacts, social issues, and ethical concerns. However, in recent years, there has been a growing recognition of the need to promote sustainability within the RMG industry. Here are some key areas where sustainability is affiliated with the RMG sector: Environmental Impact: The RMG sector has significant environmental implications, including water pollution, energy consumption, and waste generation. To address these issues, sustainable practices are being adopted, such as reducing water usage through improved dyeing and finishing techniques, implementing energy-efficient manufacturing processes, and promoting recycling and waste management. Supply Chain Transparency: Promoting sustainability in the RMG sector involves ensuring transparency in the supply chain. This includes traceability of raw materials, such as cotton or synthetic fibers, to ensure they are sourced sustainably, with reduced environmental impact and adherence to fair labor practices. Social Responsibility: Sustainability in the RMG sector also emphasizes social responsibility, including fair labor practices, safe working conditions, and workers' rights. Companies are increasingly adopting social compliance initiatives, such as ethical sourcing, fair wages, and providing a safe and healthy working environment for employees. Circular Economy: Moving towards a circular economy is another key aspect of sustainability in the RMG sector. This involves designing products for longevity, recycling and reusing materials, and minimizing waste. Some initiatives include using recycled or upcycled materials, promoting garment recycling programs, and exploring innovative ways to extend the lifespan of clothing through repair and resale. Sustainable Fashion: The concept of sustainable fashion is gaining momentum in the RMG sector. It encourages the use of eco-friendly materials, such as organic cotton or recycled fibers, and focuses on reducing the environmental impact throughout the garment's lifecycle. Sustainable fashion also promotes slow fashion, emphasizing quality over quantity and encouraging consumers to make conscious buying decisions. Collaboration and Certification: Various collaborations and certifications are emerging to promote sustainability in the RMG sector. For example, organizations like the Sustainable Apparel Coalition (SAC) bring together brands, retailers, and manufacturers to work towards sustainability goals collectively. Certifications such as the Global Organic Textile Standard (GOTS) and FairTrade Certification ensure that certain environmental and social standards are met. Here are some of the benefits of sustainability in the RMG sector: Reduced environmental impact: By using sustainable materials, conserving water, and reducing energy consumption, the RMG sector can reduce its environmental impact. Improved worker welfare: By ensuring that workers are treated fairly and that their working conditions are safe and healthy, the RMG sector can improve worker welfare. Increased competitiveness: By adopting sustainable practices, RMG businesses can become more competitive in the global marketplace. Enhanced brand reputation: By being seen as a sustainable business, RMG businesses can enhance their brand reputation and attract customers who are concerned about sustainability. By embracing sustainability, the RMG sector can have a positive impact on the environment, workers, and businesses.

The Ready-Made Garments (RMG) sector is a significant contributor to the economy of Bangladesh, employing millions of people. The RMG sector in Bangladesh employed around 4 million workers, predominantly women. This sector plays a crucial role in generating export revenue for the country and is a major source of employment. The availability of the workforce in the RMG sector is generally high in Bangladesh due to several factors. These include: Large Population: Bangladesh has a significant population, which provides a sizable labor pool for the RMG sector. Low Skill Requirements: The entry-level positions in the RMG sector often have low skill requirements, making it easier to recruit workers. Competitive Wages: The wages offered by the RMG sector in Bangladesh, although relatively low compared to developed countries, are competitive within the local context. This attracts a steady flow of workers. Migration from Rural Areas: Many workers in the RMG sector come from rural areas in search of better economic opportunities. The sector provides them with employment and the chance to improve their living conditions. Female Workforce: The RMG sector in Bangladesh has a high participation of female workers, with women constituting a significant portion of the workforce. This is due to cultural factors, as well as the nature of work in the garment factories, which is often perceived as suitable for women. The RMG sector will need to find ways to attract and retain skilled workers if it wants to continue to grow. This will require the government to invest in education and training, and factories to provide better wages and working conditions. Here are some of the challenges and opportunities for the workforce in the RMG sector of Bangladesh: Challenges: The workforce is largely unskilled. There is a shortage of skilled workers. The population is aging and the birth rate is declining. Wages are low and working conditions are poor. Opportunities: The RMG sector is the largest export earner in Bangladesh. The government is investing in education and training. Factories are starting to provide better wages and working conditions. The demand for RMG products is growing. The RMG sector is a major driver of economic growth in Bangladesh. The workforce in the sector is facing a number of challenges, but there are also opportunities for growth. The government and the private sector need to work together to address the challenges and capitalize on the opportunities.

The COVID-19 pandemic had several positive impacts on the Readymade Garments (RMG) sector in Bangladesh. While the pandemic brought many challenges and disruptions, it also led to some positive changes and opportunities. Here are some of the positive impacts of the COVID-19 pandemic on the RMG sector in Bangladesh: Diversification of export markets: The pandemic highlighted the risks associated with depending heavily on a few key markets. As a result, Bangladesh's RMG sector focused on diversifying its export destinations. It explored new markets in Europe, Africa, and South America, reducing its reliance on traditional markets like the United States. This diversification increased market stability and reduced vulnerability to future shocks. Adoption of digital technologies: The pandemic accelerated the adoption of digital technologies in the RMG sector. To mitigate disruptions caused by lockdowns and travel restrictions, businesses embraced digital platforms for communication, order management, and virtual meetings. This shift improved operational efficiency and reduced costs associated with physical meetings and travel. Strengthening of supply chain resilience: The pandemic exposed vulnerabilities in global supply chains. To address this, the RMG sector in Bangladesh focused on strengthening its supply chain resilience. Manufacturers and exporters started developing closer relationships with suppliers and buyers, ensuring better coordination and flexibility. This resilience-building effort enabled the sector to overcome disruptions and improve its overall supply chain management. Accelerated sustainability efforts: The pandemic highlighted the importance of sustainability and responsible business practices. The RMG sector in Bangladesh, which was already making strides in this area, intensified its sustainability efforts. Many factories implemented measures to reduce energy consumption, minimize waste, and adopt eco-friendly production processes. Additionally, the crisis encouraged brands and buyers to prioritize ethical sourcing and support factories with robust sustainability practices. Workforce well-being and safety: The pandemic brought a renewed focus on the well-being and safety of the workforce in the RMG sector. Factory owners and industry stakeholders took steps to improve workplace conditions, enhance hygiene standards, and ensure social distancing measures were in place. This emphasis on employee welfare resulted in a safer and healthier working environment, benefiting the workers and contributing to the sector's overall image. Opportunities for innovation and value addition: The pandemic necessitated a shift in consumer preferences and demand. The RMG sector in Bangladesh capitalized on this opportunity to innovate and add value to their products. Manufacturers focused on producing personal protective equipment (PPE) and medical textiles, catering to the increased global demand. This diversification allowed the sector to expand its product range and explore new avenues for growth. Positive impacts: Increased investment in automation: The pandemic led to a decline in the availability of cheap labor, which forced factories to invest in automation. This investment will help the RMG sector to become more competitive in the long run. Improved working conditions: The pandemic also led to increased scrutiny of working conditions in the RMG sector. This led to some factories improving their working conditions, such as providing better ventilation and sanitation. Increased focus on quality: The pandemic led to a decline in demand for RMG products. This forced factories to focus on quality in order to retain customers. This focus on quality will help the RMG sector to become more competitive in the long run. Overall, the COVID-19 pandemic had a negative impact on the RMG sector in Bangladesh. However, there were also some positive effects, such as increased investment in automation, improved working conditions, and increased focus on quality. These positive effects will help the RMG sector to become more competitive in the long run.

Denim washing, particularly in the apparel industry, has traditionally involved processes that are resource-intensive and environmentally damaging. However, in recent years, there has been a growing focus on developing sustainable denim washing technologies that aim to reduce the ecological footprint of the denim industry. Here are some notable sustainable denims washing technologies used in the apparel industry: Laser Technology: Laser technology is increasingly being adopted as an eco-friendly alternative to traditional manual or chemical-based processes. Lasers can create various fading patterns, distressing effects, and whiskering on denim fabric without the use of water or chemicals. This technology significantly reduces water consumption, chemical usage, and energy requirements, thereby minimizing environmental impact. Ozone Washing: Ozone washing is a technique that utilizes ozone gas (O3) instead of traditional chemical-based processes to bleach and fade denim. Ozone helps break down indigo dyes and achieve desired wash effects, such as lightening the fabric and removing impurities. This technology reduces water consumption, eliminates the need for some chemicals, and decreases the overall carbon footprint associated with denim washing. Nanotechnology: Nanotechnology involves the application of nanoparticles to denim fabric to achieve different wash effects. By using nanoparticles, manufacturers can reduce the amount of water, chemicals, and energy required in the washing process. Nanotechnology allows for localized and precise treatment of denim, resulting in reduced resource consumption and enhanced sustainability. Enzyme Washing: Enzyme washing utilizes natural enzymes to break down the indigo dyes on denim fabric. Compared to traditional stone washing, enzyme washing requires less water, chemicals, and energy. Enzymes are biodegradable and have a lower environmental impact, making this process more sustainable. Recycled/Upcycled Denim: Instead of traditional washing techniques, some companies focus on using recycled or upcycled denim to create new products. This approach involves shredding old denim garments, blending the fibers with virgin or recycled materials, and spinning them into new yarns. By repurposing existing denim, the need for excessive washing and dyeing processes is minimized, reducing the environmental impact. Waterless or Reduced-Water Washing: Various techniques, such as foam washing, air washing, and steam washing, aim to minimize water usage in denim washing. Foam washing utilizes foam as a carrier for chemicals and dyes, reducing water consumption. Air washing uses air to achieve the desired wash effects, while steam washing involves the application of steam and minimal water. These waterless or reduced-water washing methods significantly decrease water consumption and wastewater generation. Here are some of the benefits of using sustainable denim washing technologies: Reduced water consumption: Sustainable denim washing technologies can help to reduce water consumption by up to 95%. This is a significant environmental benefit, as the production of denim jeans is a very water-intensive process. Reduced chemical use: Sustainable denim washing technologies can help to reduce the use of harmful chemicals. This is a health and environmental benefit, as many of the chemicals used in traditional denim washing are known to be harmful to human health and the environment. Reduced energy consumption: Sustainable denim washing technologies can help to reduce energy consumption by up to 80%. This is an environmental benefit, as the production of denim jeans is a very energy-intensive process. Improved quality: Sustainable denim washing technologies can help to improve the quality of denim garments. They can produce a more even and consistent wash, which can make denim garments look and feel better. These sustainable denim washing technologies offer the apparel industry more environmentally friendly alternatives to traditional denim washing processes. By adopting these technologies, companies can minimize water usage, chemical usage, energy consumption, and waste generation, leading to a more sustainable denim production cycle.

Minimizing reworks and improving quality and productivity are crucial goals in the apparel industry. By implementing effective strategies, organizations can reduce waste, enhance customer satisfaction, and increase profitability. Here are some approaches to achieve these objectives: Robust Quality Control Systems: Implementing robust quality control processes at every stage of production is essential. This includes conducting thorough inspections of raw materials, monitoring manufacturing processes, and performing final product inspections. Implementing statistical process control (SPC) techniques can help identify and address quality issues early, reducing the need for rework. Use high-quality raw materials: This is one of the most important things that apparel manufacturers can do to minimize rework. Poor-quality raw materials can lead to a number of defects, such as holes, tears, and fading. Employee Training and Engagement: Investing in training programs for employees is crucial to ensure they have the necessary skills to perform their tasks accurately. Training should focus on quality standards, product specifications, and efficient production techniques. Engaging employees in continuous improvement initiatives and fostering a culture of quality can significantly reduce errors and reworks. Standardized Work Procedures: Developing standardized work procedures and clearly documenting them helps eliminate ambiguity and ensures consistency in processes. Standardization minimizes variations, reduces errors, and facilitates easier identification of areas requiring improvement. Regularly reviewing and updating these procedures based on feedback and lessons learned further enhances quality and productivity. Supplier Management: Collaborating closely with suppliers and establishing clear quality standards and specifications can help prevent issues related to raw materials and components. Regularly assessing suppliers' performance, conducting audits, and providing feedback can lead to improved material quality and reduce reworks caused by substandard inputs. Root Cause Analysis: Whenever defects or reworks occur, it is crucial to conduct thorough root cause analysis to identify the underlying reasons. This involves investigating the process, equipment, materials, and human factors that contributed to the problem. By addressing the root causes, organizations can implement effective corrective and preventive actions, thereby minimizing reworks in the long run. Continuous Improvement Practices: Implementing lean manufacturing principles and continuous improvement methodologies such as Kaizen can lead to significant quality and productivity improvements. Encouraging employees to identify and address process inefficiencies, waste, and quality issues on an ongoing basis fosters a culture of continuous improvement and reduces the likelihood of reworks. Technology Adoption: Utilizing technology solutions can streamline operations, enhance quality control, and improve productivity. For example, implementing computer-aided design (CAD) systems, product lifecycle management (PLM) software, and enterprise resource planning (ERP) systems can optimize processes, reduce errors, and improve communication across departments. Real-time Data Monitoring and Analysis: Deploying data monitoring systems and real-time analytics allows organizations to track key performance indicators (KPIs) and identify trends or anomalies promptly. This enables proactive decision-making, early detection of quality issues, and prompt corrective actions, ultimately reducing rework requirements. Collaboration and Communication: Facilitating effective collaboration and communication among different departments and stakeholders is crucial. Clear communication channels help address issues promptly, prevent misunderstandings, and ensure everyone is aligned with quality objectives. Regular meetings, cross-functional teams, and collaborative problem-solving approaches can drive quality and productivity improvements. Feedback from Customers: Actively seeking and analyzing customer feedback can provide valuable insights into product quality, design flaws, and customer preferences. By incorporating customer input into the design and production processes, organizations can proactively address potential quality issues and reduce rework requirements. There are a number of things that apparel manufacturers can do to minimize rework. These include: Using high-quality raw materials Training workers on how to identify and fix defects Maintaining and repairing equipment regularly Implementing a comprehensive quality control program Communicating with customers about changes in design or specifications Setting realistic production schedules By taking steps to minimize rework, apparel manufacturers can improve their quality, productivity, and profitability. Implementing these strategies requires commitment, continuous monitoring, and a strong focus on quality improvement. By minimizing reworks, the apparel industry can enhance product quality, meet customer expectations, and achieve sustainable productivity gains.

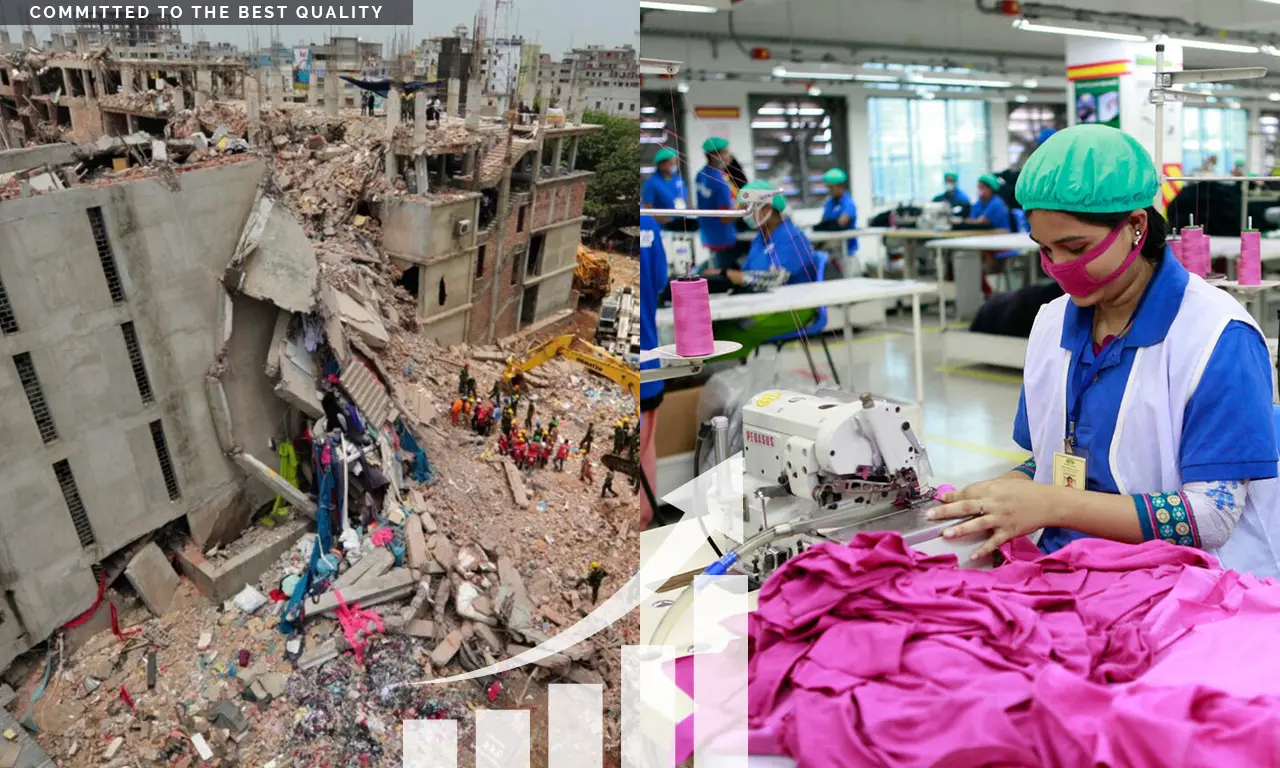

The apparel manufacturing industry in Bangladesh plays a significant role in the country's economy, employing millions of workers and accounting for a substantial portion of its export revenue. Over the years, the industry has faced numerous challenges related to sustainability, including environmental impact, labor rights, and worker safety. Efforts have been made to address these issues, but there is still progress to be made. Environmental Sustainability: Water and Energy Management: The apparel industry is a water-intensive sector. Some factories have implemented water recycling and conservation practices, reducing water usage. Similarly, efforts have been made to improve energy efficiency by adopting renewable energy sources and energy-saving technologies. Chemical Management: The industry has faced criticism for its use and discharge of hazardous chemicals. Initiatives like the "Detox Campaign" by environmental organizations have urged brands and manufacturers to eliminate the use of harmful substances and promote the use of safer alternatives. Waste Management: Waste generation is a major concern. Some factories have implemented waste management systems, including recycling and waste segregation, to minimize the environmental impact. Efforts have also been made to reduce packaging waste. Labor Rights and Social Sustainability: Worker Safety: Bangladesh has faced tragic incidents, such as factory fires and building collapses, highlighting the need for improved worker safety. The Accord on Fire and Building Safety and the Alliance for Bangladesh Worker Safety were initiatives that aimed to enhance workplace safety standards. However, they concluded their operations in 2018, and ongoing efforts focus on the implementation of sustainable safety measures. Fair Wages and Working Conditions: There have been calls for fair wages and improved working conditions for garment workers. Initiatives like the Bangladesh Accord and the Bangladesh Garment Manufacturers and Exporters Association (BGMEA) have worked to address these issues, although there is still room for improvement. Social Compliance and Labor Standards: Efforts have been made to enhance social compliance and ensure adherence to labor standards. Brands and manufacturers have adopted codes of conduct and implemented monitoring systems to address issues like child labor, forced labor, and discrimination. Challenges and Way Forward: Despite progress, the apparel manufacturing industry in Bangladesh continues to face challenges on the path towards sustainability. Some key areas to focus on include: Capacity Building: Enhancing the knowledge and skills of manufacturers, workers, and relevant stakeholders in sustainable practices and technologies. Collaboration and Partnerships: Encouraging collaboration between brands, manufacturers, NGOs, and government bodies to develop and implement sustainable practices. Transparency and Traceability: Improving supply chain transparency and traceability to ensure compliance with sustainability standards and address issues such as worker exploitation and environmental impact. Policy and Regulation: Strengthening regulatory frameworks and implementing policies that incentivize and enforce sustainable practices within the industry. In recent years, there has been a growing focus on sustainability in the apparel manufacturing industry in Bangladesh. This is due to a number of factors, including: The increasing awareness of the environmental impact of the industry. The growing demand for ethical and sustainable clothing from consumers. The pressure from international brands and retailers to improve the working conditions in garment factories in Bangladesh. Overall, the apparel manufacturing industry in Bangladesh has made efforts to address sustainability challenges, but ongoing commitment, collaboration, and continuous improvement are crucial to achieving long-term sustainability goals.

The workers' satisfaction towards the Ready-Made Garment (RMG) industry in Bangladesh can vary based on individual experiences and circumstances. While it is challenging to provide a comprehensive assessment, but here is the general overview of the factors that influence workers' satisfaction in the RMG industry. A 2019 study by the International Labour Organization (ILO) found that the average wage for RMG workers in Bangladesh is $380 per month. This is significantly lower than the minimum wage of $810 per month set by the government. The study also found that working conditions in RMG factories are often poor, with long hours, low pay, and a lack of safety regulations. Despite these challenges, many RMG workers in Bangladesh are satisfied with their jobs. A 2018 survey by the Bangladesh Garment Manufacturers and Exporters Association (BGMEA) found that 75% of RMG workers are satisfied with their jobs. The survey also found that 85% of RMG workers would recommend their jobs to others. There are a number of reasons why RMG workers in Bangladesh are satisfied with their jobs. First, RMG jobs are relatively easy to get. Bangladesh has a large pool of unemployed workers, and RMG factories are always looking for new employees. Second, RMG jobs pay better than most other jobs in Bangladesh. Third, RMG jobs offer opportunities for advancement. Workers who are hard-working and dedicated can often move up the ranks in an RMG factory. However, there are also a number of reasons why RMG workers in Bangladesh are not satisfied with their jobs. First, wages are low. The average wage of $380 per month is not enough to support a family in Bangladesh. Second, working conditions are often poor. RMG factories are often overcrowded and noisy. Third, there is a lack of safety regulations in RMG factories. This has led to a number of accidents and deaths in recent years. Wages and Benefits: Adequate compensation is a crucial factor in determining workers' satisfaction. In the past, low wages and poor working conditions have been common issues in the RMG industry in Bangladesh. However, efforts have been made to improve wages and provide benefits such as overtime pay, bonuses, and healthcare facilities. Working Conditions: Safe and comfortable working conditions are essential for workers' satisfaction. In the past, safety standards in some factories were subpar, leading to accidents and loss of lives. However, significant progress has been made in improving workplace safety through initiatives like the Accord on Fire and Building Safety and the Alliance for Bangladesh Worker Safety. Working Hours and Overtime: Excessive working hours and overtime can impact workers' satisfaction. In the past, long working hours were common in the RMG industry. Efforts have been made to address this issue, and legally mandated working hours have been implemented. However, compliance with these regulations and the prevalence of excessive overtime can still vary. Job Security: Workers' satisfaction can be influenced by job security and stability. In the past, some workers faced job insecurity due to factory closures or layoffs. Steps have been taken to improve job security in the industry, but challenges persist. Social and Welfare Programs: Access to social and welfare programs, such as education and healthcare, can contribute to workers' satisfaction. Some garment factories have implemented initiatives to provide education, healthcare services, and daycare facilities for workers and their families. Unionization and Collective Bargaining: Workers' ability to organize and bargain collectively can positively impact their job satisfaction. The formation of trade unions has been encouraged in the RMG industry, but there have been challenges in establishing effective union representation. It is important to note that while improvements have been made in the RMG industry, there are still ongoing issues and room for further progress. Different factories and brands may have varying levels of compliance with labor standards and worker satisfaction. Efforts from government, industry stakeholders, and international collaborations are necessary to address these challenges and enhance workers' satisfaction in the RMG industry in Bangladesh.

Bangladesh's ready-made garment industry is one of the largest in the world and a significant contributor to the country's economy. However, the industry has faced various challenges, including issues related to workers' rights, safety, and wages. Here are some key points regarding the status of workers in the RMG industry in Bangladesh: Working conditions: Historically, there have been concerns about poor working conditions in the industry. These include overcrowded factories, inadequate ventilation, lack of proper sanitation facilities, and long working hours. Workers have often faced challenges such as low pay, excessive overtime, and limited job security. Safety: The industry gained global attention due to several tragic incidents, such as the Rana Plaza building collapse in 2013, which resulted in the loss of more than 1,100 lives. These incidents highlighted the need for improved safety standards in garment factories. Since then, efforts have been made to enhance workplace safety, including the implementation of the Accord on Fire and Building Safety in Bangladesh and the Alliance for Bangladesh Worker Safety. Worker rights and organizations: Workers' rights have been a subject of concern, including issues related to freedom of association, collective bargaining, and workers' representation. Several trade unions and labor organizations have been advocating for better conditions and workers' rights in the RMG sector. Minimum wage: The Bangladesh government periodically revises the minimum wage for RMG workers. However, concerns have been raised about the adequacy of these wages, as they may not meet the living costs and basic needs of workers. Progress and initiatives: Over the years, there have been efforts by both international stakeholders and local organizations to improve the conditions of RMG workers in Bangladesh. These initiatives include inspections, training programs, capacity building, and collaborations between brands, factory owners, and labor organizations. Government initiatives The government of Bangladesh has taken some steps to improve the working conditions of garment workers. In 2013, the government raised the minimum wage for garment workers to $380 per month. The government has also implemented a number of safety regulations in garment factories. NGO initiatives A number of non-governmental organizations (NGOs) are working to improve the working conditions of garment workers in Bangladesh. These NGOs provide training to workers on their rights, and they also work to improve working conditions in factories. Conclusion: The present status of workers in ready-made garments industries in Bangladesh is mixed. There are a number of challenges that need to be addressed in order to improve the working conditions of garment workers. However, there are also a number of initiatives that are being taken by the government and NGOs to improve the situation.

The Rana Plaza incident, which occurred on April 24, 2013, was a catastrophic building collapse in Savar, Bangladesh. The building housed several garment factories, and the incident resulted in the death of over 1,100 people and injured thousands of others. This tragic event brought significant attention to the working conditions and safety standards in the Ready-Made Garment (RMG) industry in Bangladesh. A comparative analysis of the RMG industry before and after the Rana Plaza incident reveals several important changes and developments. 1) Safety and Building Standards: Before Rana Plaza: Prior to the incident, safety standards and building regulations in the RMG industry in Bangladesh were often inadequate. Many factories operated in buildings that were structurally unsound, lacked proper fire safety measures, and were overcrowded. Workers faced numerous hazards, such as inadequate fire exits, locked emergency exits, and poor electrical wiring. After Rana Plaza: The Rana Plaza disaster served as a wake-up call for the industry and prompted significant changes in safety and building standards. The Bangladeshi government, international organizations, and industry stakeholders took action to improve workplace safety. The Accord on Fire and Building Safety in Bangladesh and the Alliance for Bangladesh Worker Safety were established, leading to the inspection and remediation of thousands of factories. The government also introduced new laws and regulations to ensure compliance with safety standards. 2) Worker Rights and Unionization: Before Rana Plaza: Workers' rights and the ability to unionize were often suppressed in the RMG industry. Many workers faced unsafe working conditions, low wages, long working hours, and limited or no access to social protections. Union activities were often met with resistance, and workers faced the risk of losing their jobs or facing other forms of retaliation. After Rana Plaza: The Rana Plaza incident drew global attention to the plight of workers in the RMG industry. There was an increased focus on workers' rights, fair wages, and the right to unionize. The tragedy spurred conversations about labor reforms and social responsibility within the industry. Efforts were made to strengthen workers' rights, improve labor laws, and increase collective bargaining power. Several international initiatives and organizations also supported workers' rights and unionization efforts in Bangladesh. 3) Transparency and Supply Chain Accountability: Before Rana Plaza: Supply chains in the RMG industry often lacked transparency, making it difficult for brands and consumers to track the origins of their garments. The complex supply chain structure often led to subcontracting, where factories outsourced production to smaller, less regulated facilities. This lack of transparency made it challenging to hold brands and manufacturers accountable for labor and safety standards. After Rana Plaza: The Rana Plaza incident prompted increased scrutiny and demand for transparency in the garment industry. Brands and retailers faced mounting pressure to ensure responsible sourcing practices and improve supply chain transparency. Initiatives such as the Bangladesh Accord and Alliance required participating brands to disclose their supplier factories and commit to remediation efforts. Consumers also became more aware and conscious of ethical and sustainable fashion, driving the demand for transparent and accountable supply chains. The following table provides a comparative analysis of the RMG industry in Bangladesh before and after the Rana Plaza incident: Indicator Before Rana Plaza After Rana Plaza Number of factories 4,500 4,800 Number of workers 4 million 4.5 million Export value $21 billion $30 billion Minimum wage $300 per month $380 per month Safety regulations Few Many Inspections Few Many Initiatives Few Many Overall, the Rana Plaza incident had a profound impact on the RMG industry in Bangladesh. It brought about significant changes in safety standards, worker rights, and supply chain transparency. While challenges remain, the incident served as a catalyst for positive reforms and raised global awareness about the need for ethical and responsible practices in the garment industry.

The ready-made garment (RMG) industry of Bangladesh is one of the largest and most important sectors of the country's economy. The industry has been growing rapidly in recent years, and now accounts for over 80% of Bangladesh's total export earnings. The RMG industry has a significant impact on the overall economy of Bangladesh. It provides employment to millions of people, and contributes a large share of the country's GDP. The industry also helps to promote economic development in Bangladesh by providing a source of foreign exchange and by stimulating investment in other sectors of the economy. The RMG industry in Bangladesh is facing a number of challenges. These include rising labor costs, competition from other low-cost countries, and the need to improve quality and productivity. However, the industry is well-positioned to continue to grow in the coming years, as demand for apparel continues to grow in the global market. Here are some of the business trends that are expected to shape the RMG industry in Bangladesh in the coming years: Rising labor costs: Labor costs in Bangladesh are rising, which is putting pressure on the profitability of the RMG industry. However, the industry is expected to continue to grow, as it is still one of the most cost-competitive in the world. Competition from other low-cost countries: Bangladesh is facing increasing competition from other low-cost countries, such as Vietnam and Cambodia. These countries are offering even lower labor costs, which is making it difficult for Bangladesh to compete. Need to improve quality and productivity: The RMG industry in Bangladesh needs to improve quality and productivity in order to remain competitive. This will require investment in new technology and training for workers. Despite these challenges, the RMG industry in Bangladesh is expected to continue to grow in the coming years. The industry is still one of the most cost-competitive in the world, and it is well-positioned to benefit from the growing demand for apparel in the global market. Here are some of the opportunities that exist for the RMG industry in Bangladesh: Growing demand for apparel: The global demand for apparel is growing, and Bangladesh is well-positioned to benefit from this growth. The country has a large and growing population, and it is also located in a strategic location near major markets in Europe and Asia. Expanding into new markets: Bangladesh can expand into new markets, such as the United States and Europe. These markets offer large and growing populations, and they are also relatively affluent. Upgrading technology: Bangladesh can upgrade its technology in order to improve quality and productivity. This will make the industry more competitive and will help it to attract new customers. The RMG industry in Bangladesh is facing a number of challenges, but it also has a number of opportunities. The industry is expected to continue to grow in the coming years, and it is well-positioned to benefit from the growing demand for apparel in the global market. Here are some of the business trends that are expected to shape the RMG industry in Bangladesh in the coming years: The growth of online shopping: The growth of online shopping is expected to lead to an increase in demand for garments from Bangladesh. This is because Bangladesh is a major supplier of low-cost garments. The rise of sustainable fashion: The rise of sustainable fashion is expected to lead to an increase in demand for garments that are made from sustainable materials and that are produced in a sustainable way. Bangladesh is well-positioned to meet this demand, as the country has a long history of producing garments using sustainable methods. The increasing focus on quality: Buyers are increasingly focusing on quality when it comes to garments. This means that garment manufacturers in Bangladesh will need to focus on improving the quality of their products. The need for innovation: The RMG industry in Bangladesh will need to continue to innovate in order to stay ahead of the competition. This means that garment manufacturers will need to invest in new technologies and new ways of doing things. The RMG industry in Bangladesh is facing a number of challenges, but it is also well-positioned to take advantage of a number of opportunities. The industry is expected to continue to grow in the coming years, and it is likely to become even more important to the country's economy.

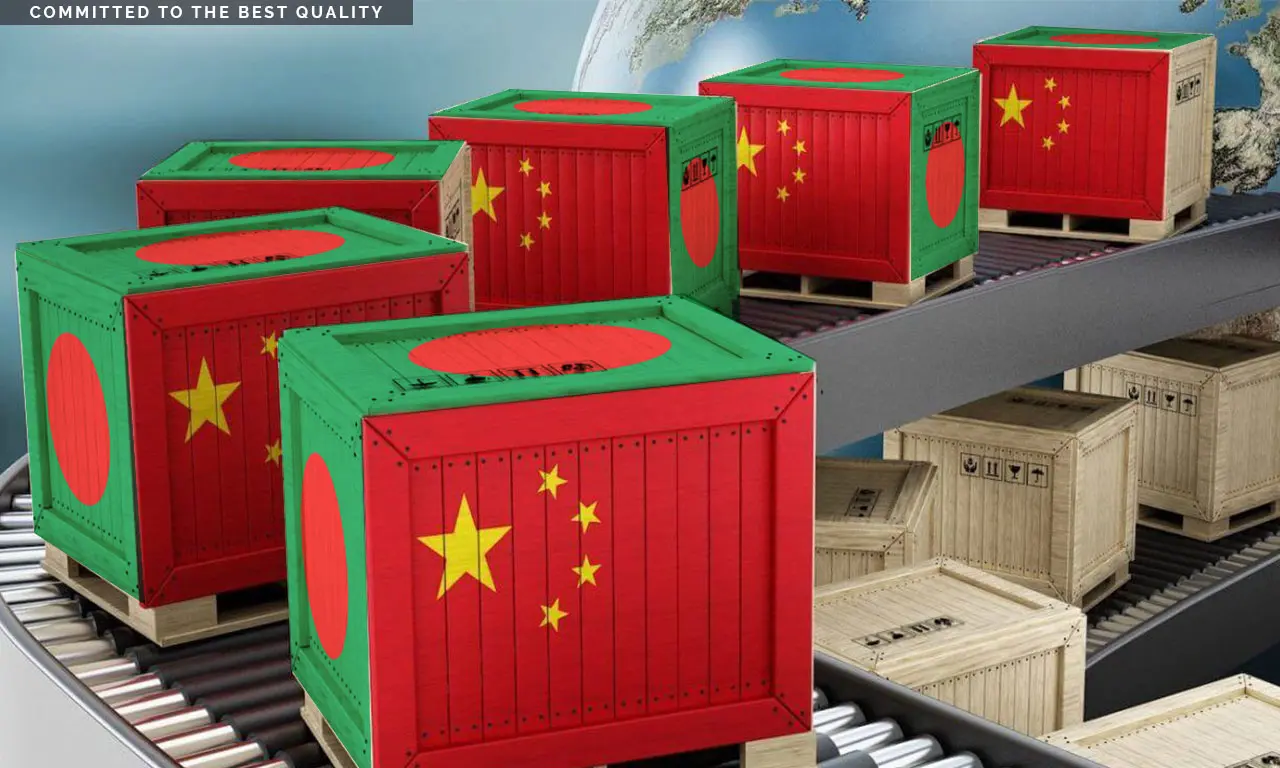

The export scenario between Bangladesh and China in the Ready-Made Garments (RMG) sector presents several opportunities for Bangladesh. The RMG industry has played a vital role in Bangladesh's economic growth, and China has been a significant player in the global textile and apparel market. Here are some opportunities for Bangladesh in the RMG sector when it comes to exporting to China: Bangladesh and China are the two largest exporters of ready-made garments (RMG) in the world. In 2021, Bangladesh exported $34.1 billion worth of RMG, while China exported $288.7 billion worth of RMG. This means that China is still the dominant player in the RMG market, but Bangladesh is catching up fast. There are a number of factors that are driving the growth of the RMG industry in Bangladesh. These factors include: The low cost of labor in Bangladesh. The improved quality of garments produced in Bangladesh. The growing demand for RMG from developed countries. Bangladesh is also well-positioned to take advantage of a number of opportunities in the RMG market. These opportunities include: The growth of online shopping. The rise of sustainable fashion. The increasing focus on quality. The need for innovation. Bangladesh is already a major supplier of RMG to developed countries. However, the country has the potential to become an even larger supplier in the coming years. By taking advantage of the opportunities that are available, Bangladesh can continue to grow its RMG industry and become a major player in the global market. Lower production costs: Bangladesh offers lower production costs compared to China, which provides a competitive advantage. Factors like lower labor costs, availability of skilled and semi-skilled workers, and relatively lower operational expenses make Bangladesh an attractive sourcing destination for Chinese buyers. Preferential trade agreements: Bangladesh enjoys preferential trade agreements with China, such as the Asia-Pacific Trade Agreement (APTA) and the Bangladesh-China Free Trade Agreement (BCFTA). These agreements provide tariff concessions, reduced customs duties, and trade facilitation measures, making it easier for Bangladesh to export RMG products to China. Diversification of sourcing: With rising labor costs in China, Chinese manufacturers and buyers are increasingly looking for alternative sourcing options. Bangladesh's RMG industry offers a viable alternative due to its competitive pricing and ability to handle large-scale production orders. Rising demand in China: China has a growing middle class with increasing disposable income, leading to a rise in consumer demand for affordable and trendy clothing. Bangladesh, with its capability to produce a wide range of garments at competitive prices, can tap into this expanding market and meet the demand for ready-made garments in China. Sustainable and ethical production: There is an increasing global demand for sustainable and ethically produced garments. Bangladesh has been making progress in improving its compliance with social and environmental standards in the RMG sector. This presents an opportunity for Bangladesh to position itself as a responsible sourcing destination for Chinese buyers who prioritize sustainability and ethical production practices. Product diversification: Bangladesh has primarily been known for producing basic garments like shirts, trousers, and knitwear. However, there is an opportunity for Bangladesh to diversify its product range and offer value-added items such as high-quality fashion garments, sportswear, outerwear, and accessories. This can help cater to the evolving preferences of Chinese consumers and expand the export portfolio. Collaborative partnerships: Bangladesh and China can foster collaborative partnerships in the RMG sector. Chinese manufacturers can invest in Bangladesh's garment industry, bringing advanced technology, expertise, and market knowledge. Such partnerships can enhance the productivity, efficiency, and quality of Bangladesh's RMG sector, enabling it to cater to the demands of the Chinese market more effectively. It's important to note that while there are opportunities, there may also be challenges such as competition from other sourcing destinations, the need for further improvements in infrastructure and logistics, and maintaining compliance with international standards. Nonetheless, with strategic planning, investments in skill development, and continuous improvements, Bangladesh can leverage the export opportunities in the RMG sector when it comes to China.

Green supply chain management (GSCM) is a set of practices that organizations can use to reduce the environmental impact of their supply chains. GSCM can be implemented in the ready-made garment (RMG) sector of Bangladesh by following these steps: Set environmental goals: The first step is to set environmental goals for the supply chain. These goals should be specific, measurable, achievable, relevant, and time-bound. For example, a goal could be to reduce water consumption by 10% in the next year. Identify environmental impacts: The next step is to identify the environmental impacts of the supply chain. This can be done by conducting an environmental impact assessment. The assessment should identify the major environmental impacts of the supply chain, such as water consumption, energy consumption, and waste generation. Develop and implement green practices: Once the environmental impacts have been identified, green practices can be developed and implemented to reduce these impacts. Green practices can include things like using recycled materials, reducing energy consumption, and minimizing waste. Measure and monitor progress: It is important to measure and monitor progress towards the environmental goals. This can be done by collecting data on environmental performance, such as water consumption, energy consumption, and waste generation. The data can then be used to identify areas where improvements can be made. Continuous improvement: GSCM is a continuous improvement process. As the organization learns more about the environmental impacts of its supply chain, it can develop new green practices and improve existing practices. Supplier Evaluation and Selection: Assess the environmental performance of potential suppliers. Consider factors such as waste management, energy efficiency, water conservation, and compliance with environmental regulations. Give preference to suppliers with sustainable practices and certifications. Sustainable Material Sourcing: Identify eco-friendly and sustainable raw materials for garment production. Use organic or recycled fibers, dyes with low environmental impact, and packaging materials that are biodegradable or recyclable. Energy Efficiency and Resource Conservation: Implement energy-efficient technologies and practices in manufacturing facilities. This can include installing energy-saving equipment, optimizing production processes, and using renewable energy sources where feasible. Promote water conservation by adopting technologies like water recycling and rainwater harvesting. Waste Management and Recycling: Develop a comprehensive waste management system to reduce, reuse, and recycle waste generated during the manufacturing process. Implement segregation, recycling, and safe disposal methods for different types of waste, such as fabric scraps, packaging materials, and chemicals. Green Logistics and Transportation: Optimize transportation routes to minimize fuel consumption and emissions. Encourage the use of low-emission vehicles and explore alternative transportation modes, such as rail or sea freight, for long-distance shipments. Collaborate with logistics partners to improve efficiency and reduce environmental impacts. Collaboration with Stakeholders: Engage with employees, suppliers, customers, and relevant industry associations to create awareness and promote sustainable practices. Encourage suppliers to adopt green initiatives and provide training and incentives for employees to embrace sustainable practices. Compliance with Environmental Regulations: Stay updated with local and international environmental regulations relevant to the garment industry. Ensure compliance with standards for air and water quality, chemical management, and waste disposal. Regularly monitor and report environmental performance to relevant authorities. Certification and Labeling: Pursue eco-certifications such as LEED (Leadership in Energy and Environmental Design) or ISO 14001 to demonstrate commitment to environmental sustainability. Display eco-labels on garments to inform customers about the product's environmental attributes. Continuous Improvement and Innovation: Establish a culture of continuous improvement by regularly evaluating and monitoring the effectiveness of green initiatives. Encourage innovation in sustainable practices, technology adoption, and product design to further enhance environmental performance. Collaboration and Knowledge Sharing: Collaborate with industry peers, NGOs, and government agencies to share best practices, knowledge, and resources. Participate in industry events, conferences, and workshops focused on sustainable supply chain management. The implementation of GSCM in the RMG sector of Bangladesh can have a number of benefits, including: Reduced environmental impact. Increased efficiency. Improved quality. Reduced costs. Enhanced reputation. The RMG sector of Bangladesh is a major contributor to the country's economy. The implementation of GSCM in this sector can help to make the industry more sustainable and competitive. Here are some additional tips for implementing GSCM in the RMG sector of Bangladesh: Partner with suppliers: The RMG sector is a complex supply chain with many different stakeholders. It is important to partner with suppliers to implement GSCM. Suppliers can provide valuable insights into the environmental impacts of their operations. Use technology: Technology can be a powerful tool for implementing GSCM. There are a number of software and hardware solutions that can help to track environmental performance, identify opportunities for improvement, and communicate with stakeholders. Get employees involved: Employees are the key to the success of any GSCM initiative. It is important to get employees involved in the planning and implementation of GSCM. Employees can provide valuable insights into the environmental impacts of their work and help to identify opportunities for improvement.

The ready-made garment industry, often referred to as the apparel or clothing industry, plays a significant role in global manufacturing. As concerns about environmental sustainability have grown, there has been an increasing focus on integrating sustainable practices within this industry. Here are some key environmental sustainability requirements in the ready-made garment industry: Resource-efficient production: Garment manufacturers are expected to adopt resource-efficient production processes to minimize waste and reduce resource consumption. This includes optimizing the use of energy, water, and raw materials throughout the production cycle. Reduction of greenhouse gas emissions: Manufacturers are encouraged to reduce their greenhouse gas emissions by implementing energy-efficient technologies, transitioning to renewable energy sources, and improving the overall energy management of their facilities. This helps mitigate climate change impacts associated with the industry. Waste management and recycling: Garment manufacturers should implement effective waste management systems to minimize the generation of waste and promote recycling. This involves segregating and properly disposing of different types of waste, such as fabric scraps, packaging materials, and chemicals, while also exploring opportunities for recycling or upcycling. Chemical management: Due to the extensive use of chemicals in various stages of garment production, manufacturers must adopt responsible chemical management practices. This includes the proper handling, storage, and disposal of chemicals to prevent pollution of water bodies and soil, as well as ensuring the use of environmentally friendly and non-toxic substances where possible. Water conservation: Given the water-intensive nature of garment production, manufacturers should prioritize water conservation measures. This involves investing in water-efficient technologies, recycling and reusing water wherever feasible, and implementing water management strategies to minimize water consumption and prevent water pollution. Supply chain transparency: Brands and manufacturers are increasingly expected to ensure transparency throughout their supply chains. This includes tracking and disclosing the environmental impacts associated with garment production, as well as ensuring that suppliers and subcontractors adhere to environmental sustainability standards and practices. Certification and standards: Various certification programs and industry standards, such as the Global Organic Textile Standard (GOTS) and the Sustainable Apparel Coalition's Higg Index, provide frameworks and guidelines for environmental sustainability in the garment industry. Manufacturers can seek certification or adhere to these standards to demonstrate their commitment to sustainability. Worker welfare and social responsibility: Environmental sustainability in the ready-made garment industry is often intertwined with worker welfare and social responsibility. Ensuring safe working conditions, fair wages, and adherence to labor rights are critical aspects of sustainability within the industry. It is important to note that these requirements may vary based on regional regulations, industry initiatives, and brand-specific commitments. However, the overarching goal is to promote environmental sustainability in the ready-made garment industry and mitigate its environmental footprint.

-adoption-in-Bangladesh-ready-made-garments-industry.webp)